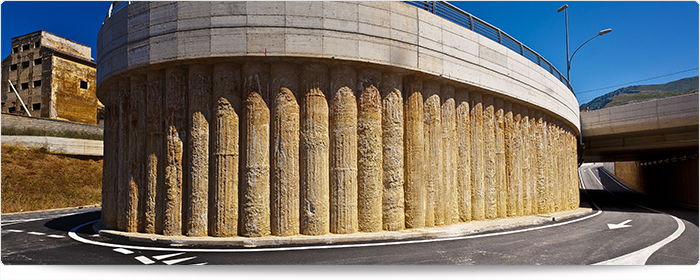

Cased augered/secant piles (CAP/CSP)

CAP/CSP technology was conceived for lined piles with the continuous flight auger method. An ideal technology for projects in urban centres, in that it eliminates vibration and disturbances to adjacent structures, reduces noise emissions and avoids the use of bentonite mud for drilling. This greatly simplifies disposal of waste material. A particularly efficient method of building secant piles for the formation of continuous structural and/or sealed bulkheads.

With CSP technology it is possible to operate in adherence with existing foundations by avoiding decompression of the soil and ensuring absolute precision: use of casing ensures a high degree of drilling verticality, with less than 0.7% deviation from the vertical position. Thanks to its constant technical improvement, this technology has significantly broadened its fields of application, allowing for a much wider range of diameters and lengths.

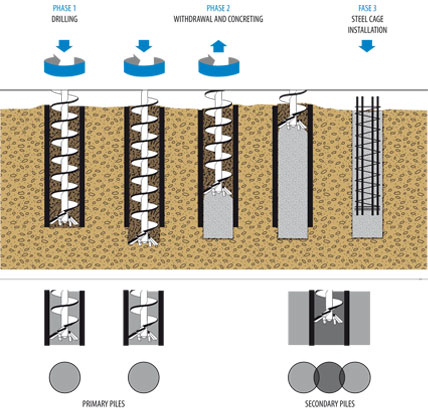

Operating specifications

In the operating phases piles are dug with simultaneous driving of the casing and the augers into the soil. When casing is completely driven the pile’s digging may continue only with the blades. Once the digging phase is finished, the blades and lining are extracted; at the same time the concrete is poured through the internal passage in the core of the blades. Once pouring is done, the cage is inserted into the still wet concrete. The continuous diaphragm is constructed with secant primary and secondary piles, properly overlapped; with this application it is necessary to construct guiding walls to ensure correct planimetric positioning of the piles and to guide the lining pipe on the surface.

Technical data

Pile diameter: 600 to 1000 mm

Maximum lined depth: 20 meters Maximum drilling depth: 25÷26 meters depending on soil diameter and consistency.

Websolute

Websolute